Commercial-Industrial Forced-Air Heating Equipment

Direct gas-fired air heaters offer safe, flexible, fuel efficient and cost effective building operation solutions. This heating equipment provides make-up air to regulate ventilation rates and offset building heat loss for millions of commercial and industrial customers.

Clean and efficient, direct gas-fired air heaters can reduce building heating costs by 30 percent or more.

The availability of direct gas-fired heaters in a variety of configurations, along with a distinguished safety record, has resulted in architects, consulting engineers, facility managers and owners increasingly specifying direct gas-fired air heaters for use in commercial and industrial buildings and processes.

To help you select a system that meets your heating and ventilation needs, AHRI provides the following guidance.

Educational Presentation: High Temperature Heating and Ventilation Technology

How it Works

Direct gas-fired air heaters blend the outside air directly with a gas flame, creating the highest possible efficiency for energy transfer. Every BTU of gas burned is delivered directly to the space.

The heated outdoor air is delivered at temperatures slightly above the ambient space temperature, offsetting air being removed by the exhaust system. Temperature controls typically maintain a constant discharge air temperature or space temperature by modulating the gas flow (typical modulation is 20:1) to adjust for varying outdoor temperatures and space needs.

During mild weather, the equipment is generally equipped with an economizer thermostat to disable the burner when the outdoor temperature approaches the desired indoor space temperature.

The clean outdoor air introduced through a direct gas-fired air heater improves the indoor air quality of the space. This equipment can be installed with a minimum amount of ductwork, providing an efficient and cost-effective installation. Additionally, the heater can be installed indoors or outdoors or in horizontal or vertical configurations permitting added flexibility.

Design Flexibility

Direct gas-fired air heaters are available in the following designs:

- Non-Recirculating: Delivers 100 percent outdoor air into the space.

- Recirculating: Delivers a mixture of outdoor air and indoor air.

Both designs are capable of delivering a wide range of outdoor air volumes to satisfy the building’s varying exhaust or ventilation requirements.

Direct Gas-Fired Heaters Solve Ventilation Problems

When a new building is designed, consideration for mechanical ventilation is generally accomplished on the front end of the project.

Tempered make-up air is designed to offset the exhaust requirements of the building; however, after the building is occupied and processes are added, it is not uncommon that the need to balance the exhaust load with tempered replacement air has been overlooked.

In many facilities, this oversight can contribute to major problems with temperature and pressure control. To solve these ventilation problems, you must start with clean outdoor air, which can be naturally introduced through a direct gas-fired air heater. The volume of clean air can be varied to meet the demands of the exhaust system and infiltration.

Managing Process Load

Process loads can vary through-out the day with, for example, intermittent paint booth operations or welding processes. Direct gas-fired heating systems are an equipment option that can allow convenient and flexible control of ventilation rates to match these loads.

If the direct-fired heater is not interlocked directly with the source of the exhaust, a Building Pressurization Control System (BPCS) can automatically adjust to meet these varying demands.

The BPCS maintains a slight positive pressure (i.e. 0.02–0.05 inches water column) in the building or space with respect to the outdoors, or an area adjacent to the space. This is achieved by either: turning on additional direct-fired air heaters, or varying the air flow of a direct-fired heater, or increasing the percentage of outside air.

If the varying ventilation loads are not addressed, negative pressure can:

- Create downdrafts in stacks, eroding indoor air quality.

- Adversely impact the normal operation of other gas-fired equipment.

- Prevent exhaust systems from functioning as designed due to added resistance.

Manages Infiltration Loads

Infiltration loads are potentially the largest source of cold drafts in a building. When infiltration enters a building, the heating system must work overtime to condition the air and reduce stratification.

When clean, tempered outdoor air is introduced through the direct gas-fired air heater, infiltration can be neutralized, improving comfort and indoor air quality.

Direct Gas-Fired Heaters: Meet Safety Standards

Manufacturers have their equipment tested by an independent third-party testing agency to certify that it complies with the most current version of the following national safety standards:

- American National Standard for non-recirculating direct gasfired air heaters, ANSI Z83.4/ CSA 3.7 (a joint U.S./Canadian standard).

- American National Standard for recirculating direct gasfired air heaters, ANSI Z83.18 (U.S. standard).

These standards specify construction requirements that address the combination of controls, burners and heating cabinets to ensure substantial and durable construction and safe operation. In addition, these standards subject the equipment to a variety of laboratory performance and safetyrelated tests. These tests are the result of years of experience in the manufacture, testing, installation, maintenance, inspection and research of this equipment.

Low Heater Emissions

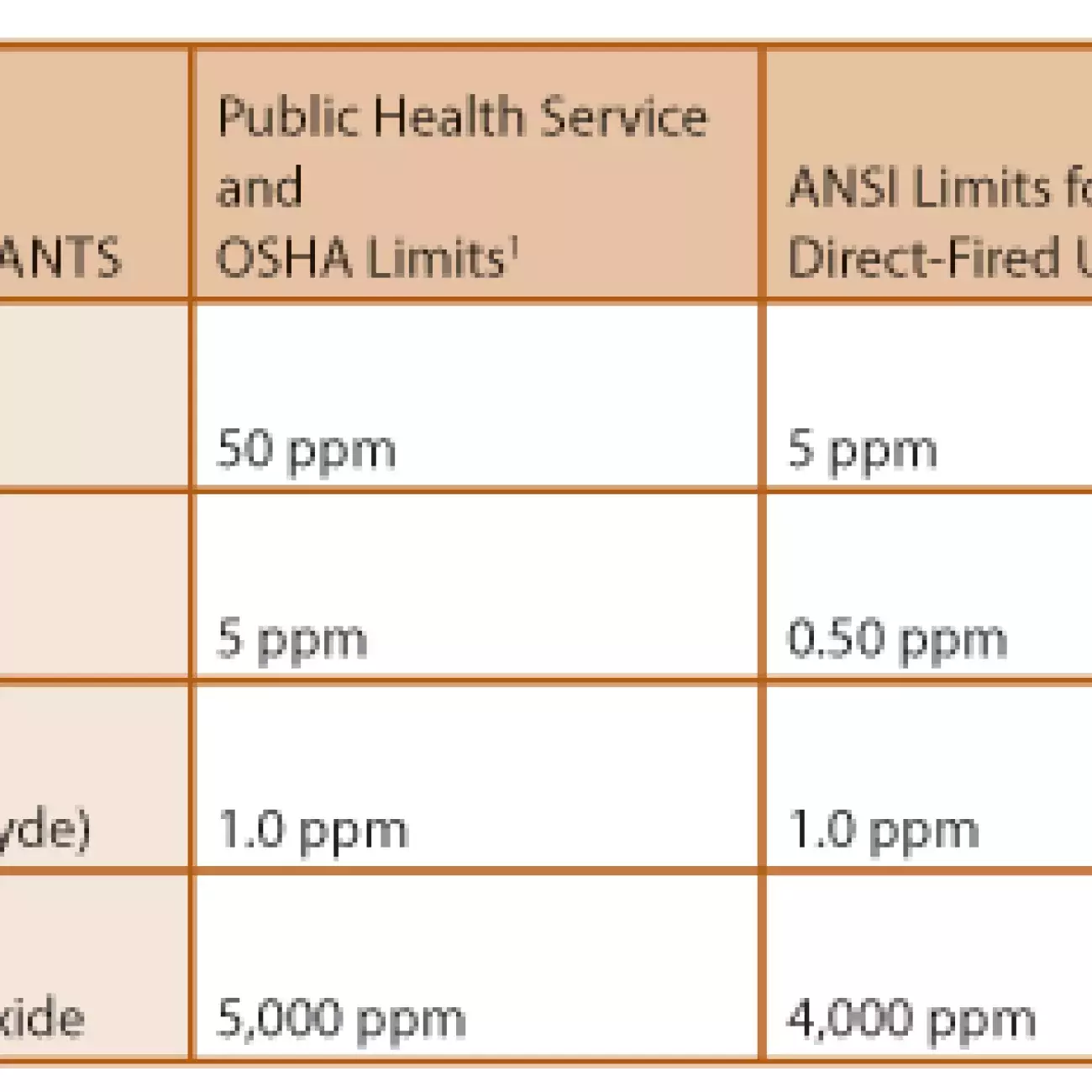

Both of the ANSI Z83.4/CSA 3.7 and ANSI Z83.18 direct gas-fired air heater standards require testing to ensure that the equipment’s emissions are below the maximum limits specified by these standards. As the Heater Emission Limits chart shows (below), the ANSI limits for direct-fired units are well below the thresholds established by OSHA and other public health organizations.

Model Code Requirements

The National Fuel Gas Code, ANSI Z223.1/NFPA 54, and the International Fuel Gas Code, both contain requirements for non-recirculating and recirculating direct-fired air heaters that reference the national safety standards. Additionally, the 2005 Edition of the Canadian B149 Gas Installation Code has included coverage for the harmonized U.S./Canadian standard for non-recirculating direct-fired air heaters.

Look for Certification Marks

Before selecting your direct-fired heater, always verify that it displays the mark of a nationally recognized testing agency, such as Intertek Testing Services (ETL), CSA International (CSA) or Underwriters Laboratories (UL).