Humidifiers

Did you know that in cold climates, when outdoor air is brought into a building and heated, the relative humidity can be as low as 10 percent — about the same as the Sahara Desert?

AHR Expo Educational Presentations

- 2016 - Humidification Done Right

- 2017 - Humidification

- 2018 - The Latest in Humidity Technologies and Applications

- 2019 – The Importance of Humidity in Modern Buildings

- Humidity and Occupants Presentation

- 2020 - Health, Comfort and Preservation: Bringing the Benefits of Humidity Home

Dry air isn’t just uncomfortable. It can cause a variety of unwanted conditions, including:

- Dry nasal passages

- Sore throats

- Increased vulnerability to infections

- Increased household dust

- Damage to woodwork and furnishings due to cracking

- Annoying static shocks

Proper humidification in homes and workplaces helps minimize the amount of unhealthy airborne pollutants and improves comfort by reducing the evaporative effect that dry air can have on the body — something merely turning up the thermostat can’t accomplish.

Humidifiers operate by creating water vapor, either by moving air over a water-soaked media or by generating steam. This water vapor is distributed directly into the home or workplace open spaces or through duct systems where water vapor is absorbed by dry air.

Read on for more on humidification technology, product basics, installation and maintenance considerations, and standards and certification.

Humidification Technology

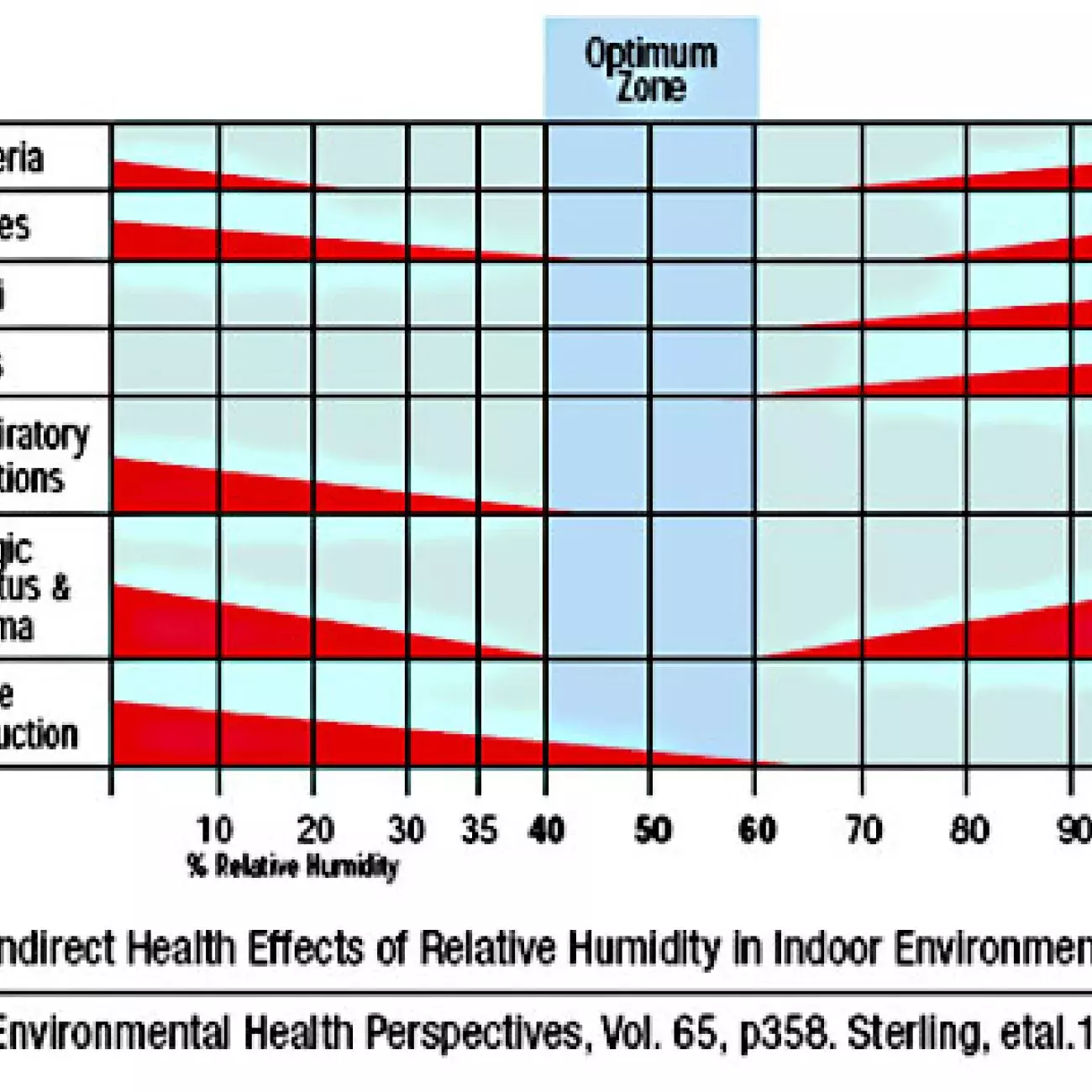

The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), along with other research, confirms that controlling indoor humidity to levels between 40 and 60 percent fosters healthy indoor living while preventing mold growth. Outside of this range, dust mites, bacteria, viruses, and fungi thrive. According to the American Society of Otolaryngology, very dry air in a home or building can make people more susceptible to infections.

Although the more common concern is providing enough humidity during heating, having too much humidity also can be problematic. That’s why it’s important to consider the following with any humidifier application:

- Select the right type (bypass, fan powered, steam, etc.)

- Select the right size (humidifier output that meets the needs of the home or workplace)

- Proper control strategy to maintain the correct humidity range

- Proper maintenance

Product Basics (Commercial/Industrial)

There are two basic categories of humidifiers: residential, and commercial/industrial. Commercial and industrial humidifiers can be divided into three types: adiabatic, direct injection steam, and heated tank. Click here to view a chart noting each type’s advantages, limitations, and potential ancillary equipment.

ADIABATIC HUMIDIFIERS

Atomizing and evaporative types

Adiabatic humidifiers provide direct evaporation of water into the air without adding external energy. Because no heat is added to evaporate the water, there is a cooling effect that is directly proportional to the amount of water evaporated. This is sometimes referred to as sensible cooling. Sensible BTUs are taken from the surrounding air, reducing air temperature.

Adiabatic humidifiers include both atomizing and evaporative humidifiers. View a detailed chart on adiabatic humidifiers here.

In general, atomizing humidifiers reduce water particles to a mist or a fog. When the fog is sprayed into a warm, dry space, the water evaporates without the addition of heat. Atomizing humidifiers typically require purified water to prevent plugged orifices or nozzles and to eliminate the distribution of mineral dust into the indoor environment. Please click on each adiabatic humidifier below to access a brief description of that particular type.

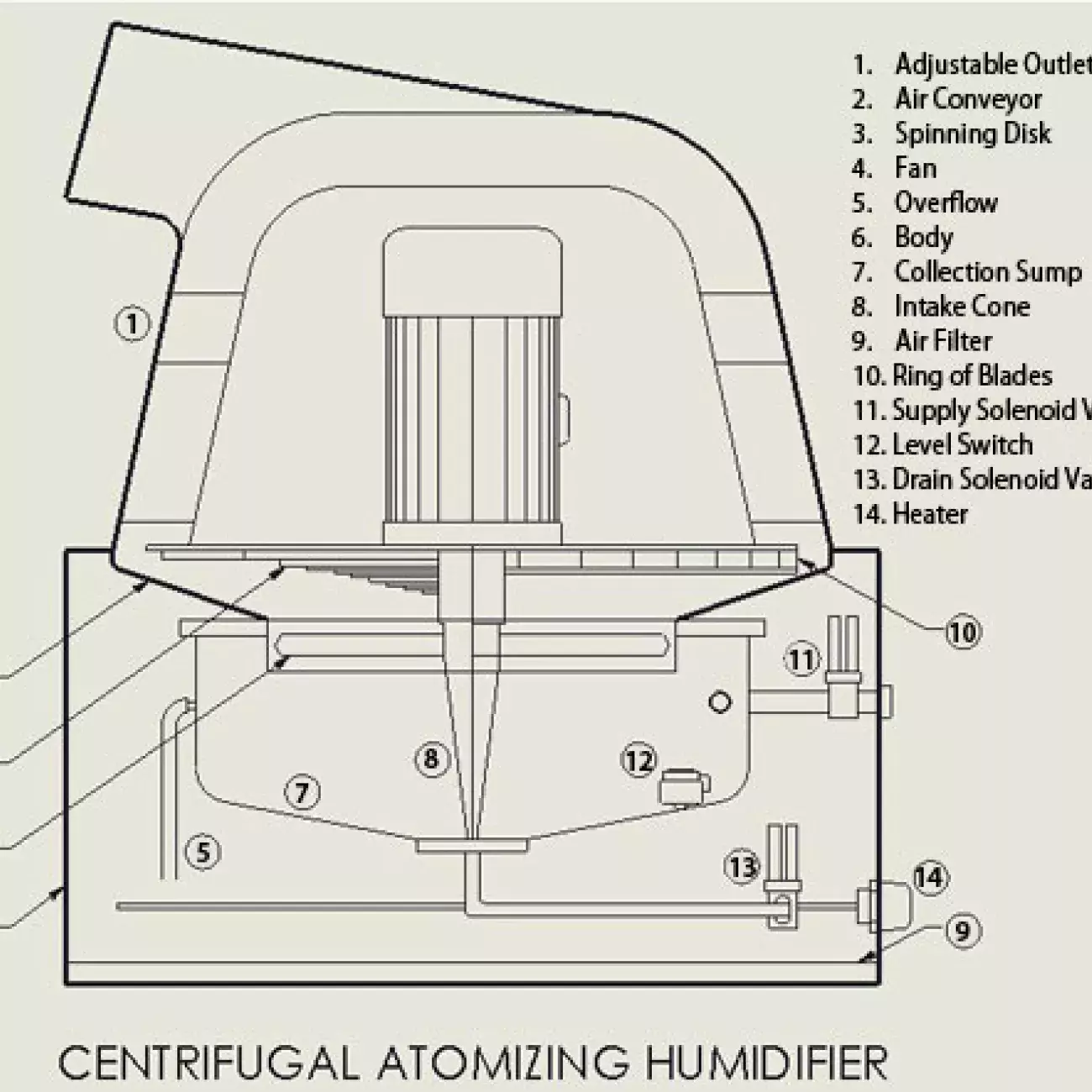

Centrifugal type atomizing humidifiers utilize a high speed disk to propel water onto plates or a comb to produce a fine mist. This mist evaporates as it enters the air.

Compressed air and water atomizing systems combine the two fluids inside a nozzle. The rapidly expanding air shears the water into atomized water particles. The mixture of atomized water and expanding air is discharged through an orifice and deflected off a resonator tip, further reducing the water particle size and resulting in a fog.

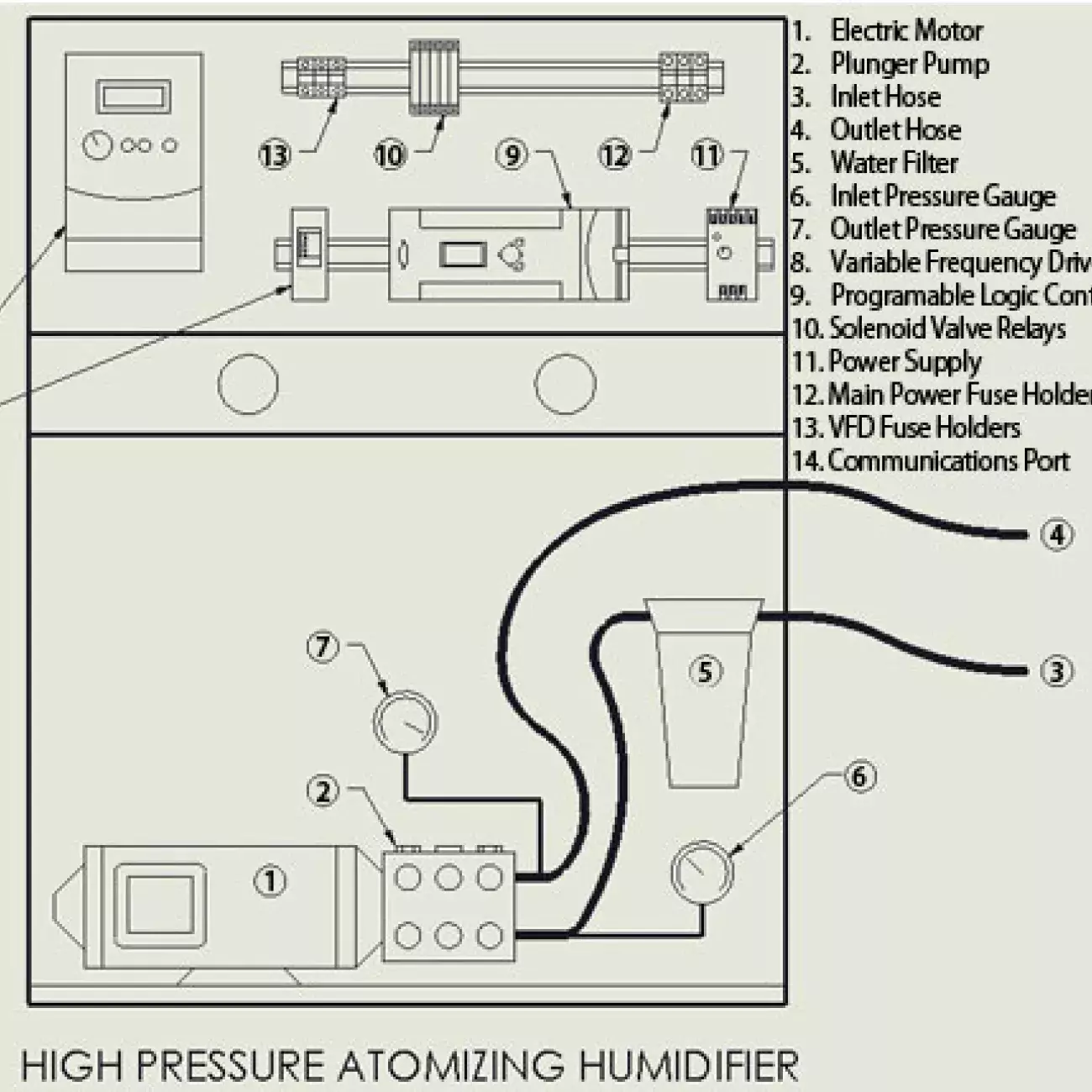

High pressure atomizing systems use a high pressure pump to force water through one or more small orifice nozzles to produce a fine mist. Humidity demand is interpreted by control logic on a Programmable Logic Controller (PLC) or circuit board. The PLC communicates with a variable frequency drive (VFD), and the VFD drives the pump, typically operating at approximately 1,000 psi water pressure. The PLC controls a series of solenoid valves, which feed the high pressure water to a series of nozzles. High pressure water passing through the nozzles leads to evaporation.

Compressed air and water atomizing systems use compressed air to produce a fine mist at the atomizer nozzle.

High pressure and compressed air and water atomizers can provide energy benefits in many applications. In air handling systems, atomizers are best located prior to a cooling coil (with drain pan) in the air handling unit. These systems also can be used for direct area discharge.

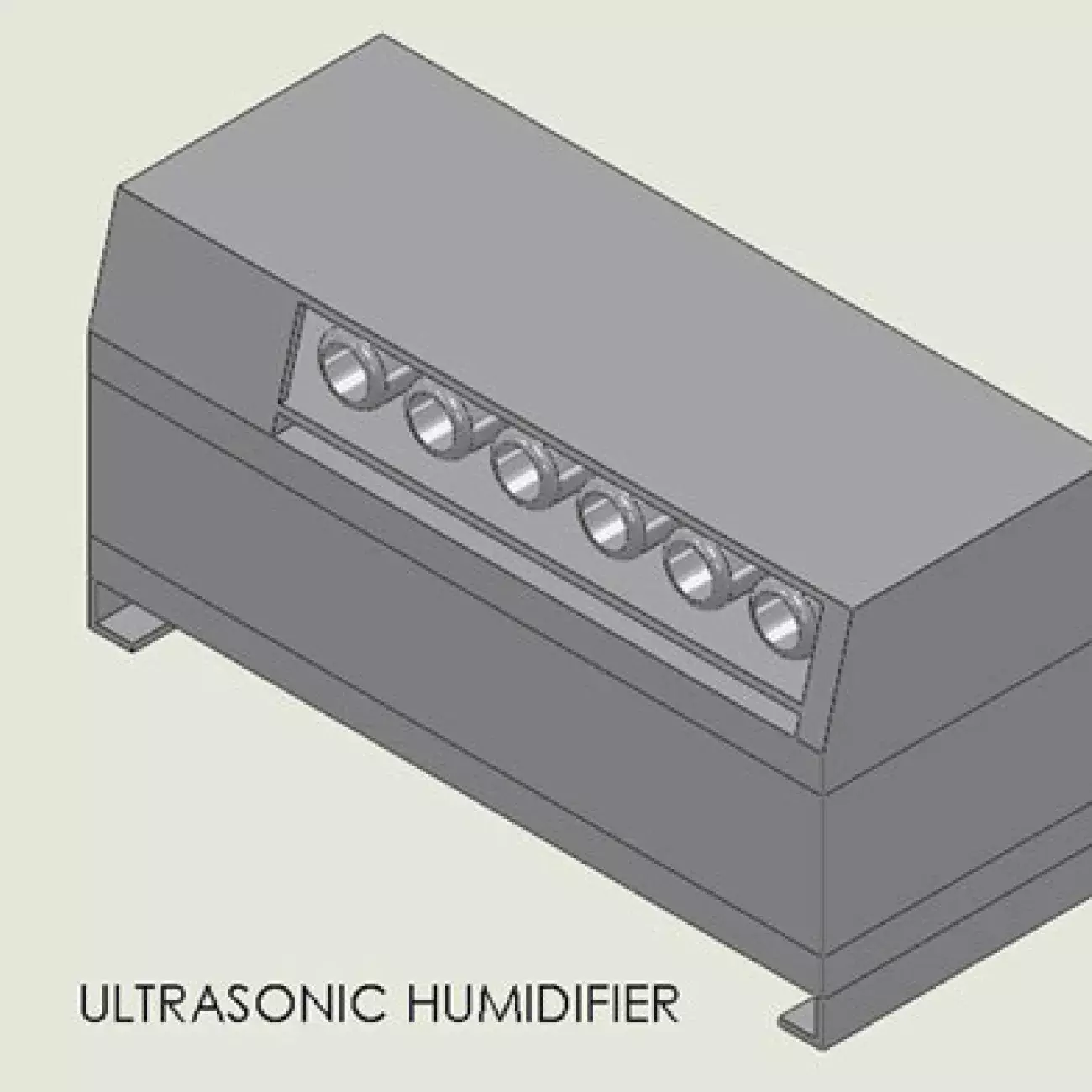

Ultrasonic atomizing systems use a piezoelectric transducer immersed in a reservoir of purified water. The transducer creates a high frequency mechanical oscillation directed at the water’s surface, which results in creation of a fine mist.

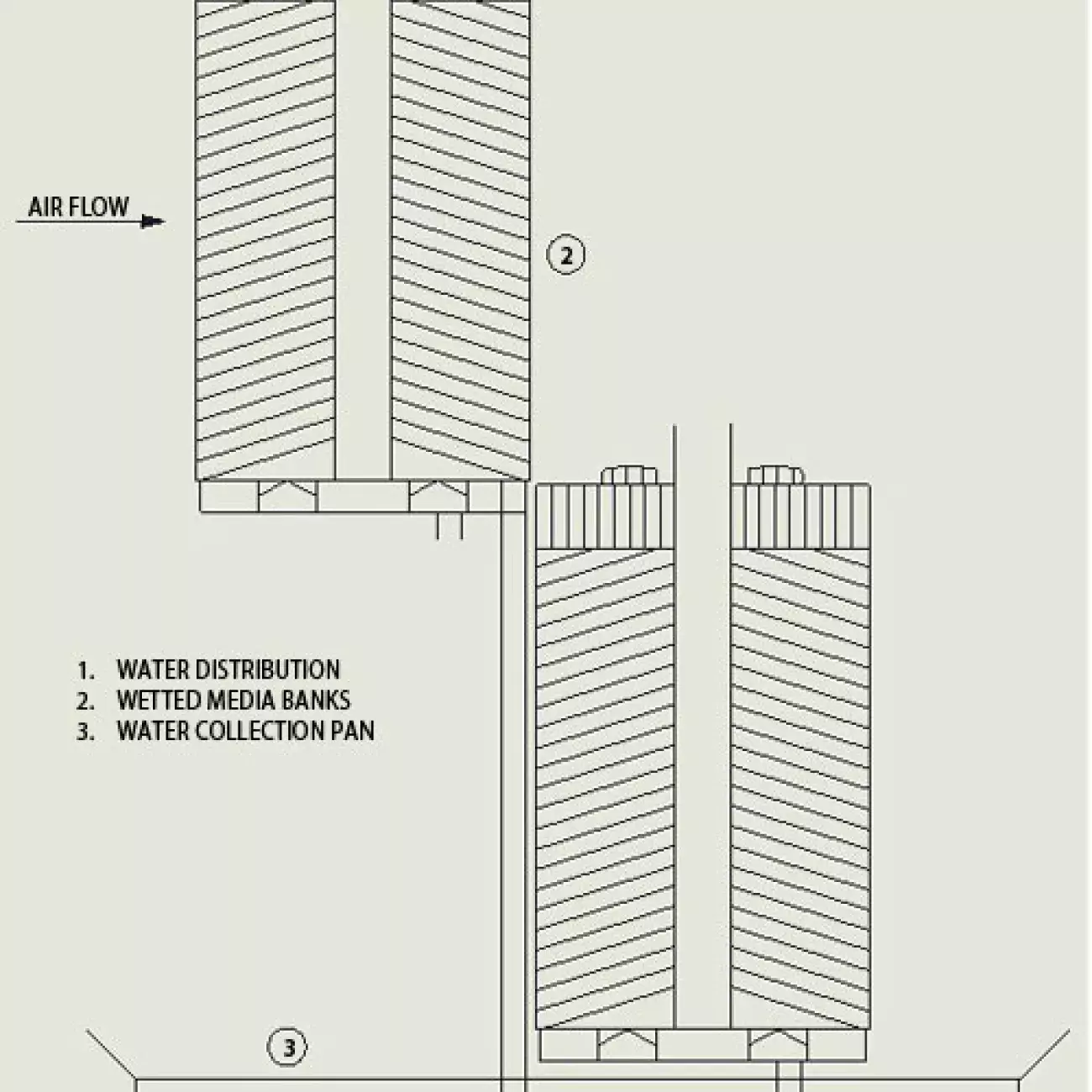

Wetted media evaporative humidifiers circulate water over a porous core media while air is blown through the openings. The rate of evaporation varies with air temperature, humidity, and velocity. Wetted media humidifiers can be designed with or without water recirculation.

DIRECT INJECTION STEAM HUMIDIFIERS

View a detailed chart on direct injection steam humidifiers here. Please click on each direct injection steam humidifier below to access a brief description of that particular type.

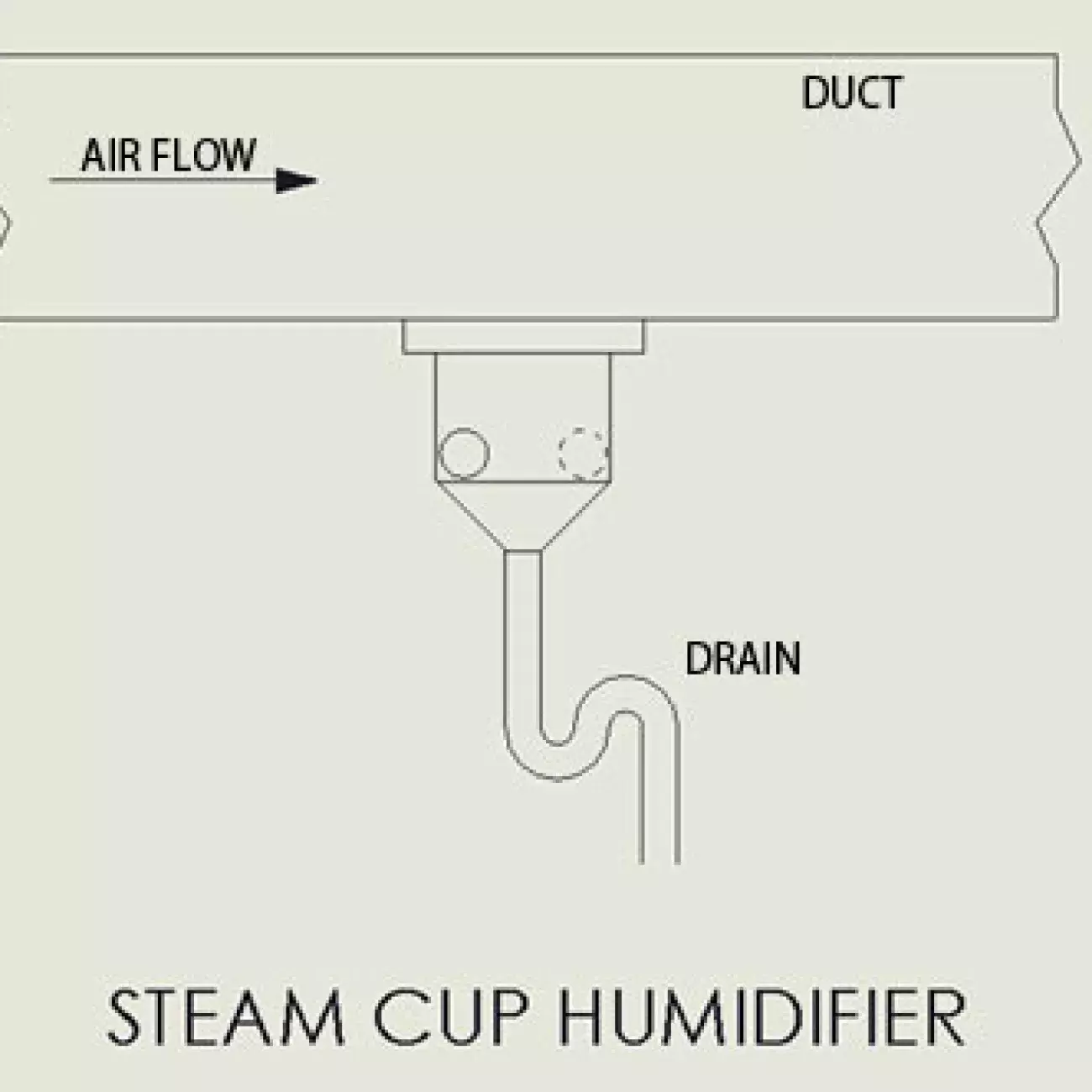

Steam cup-type humidifiers receive steam in a vessel mounted beneath an air duct. Condensate drains from the cup and steam is released into the airstream.

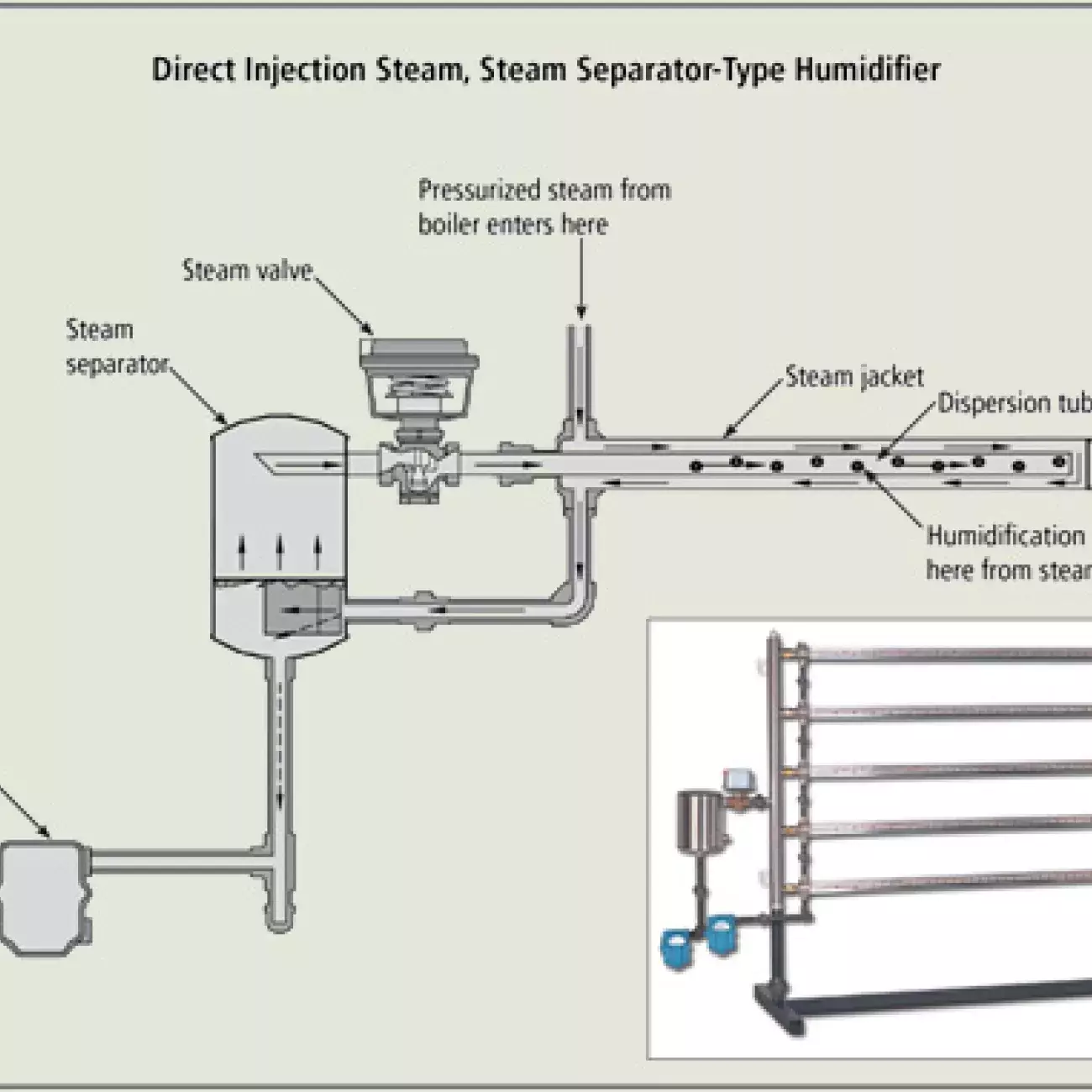

Steam separator-type humidifiers are comprised of a steam separator, integral control valve, steam jacketed dispersion tube(s), and a manifold when there is more than one dispersion tube. A steam trap and wye-type pipeline strainer are typically included in the package. Supply steam flows through the strainer and pre-heats the steam jackets before entering the separator. Liquid separates and falls with gravity through the separator drain connection to the steam trap.

High quality steam vapor travels to the control valve and, with demand for humidity, passes through the dispersion tube(s) into the airstream.

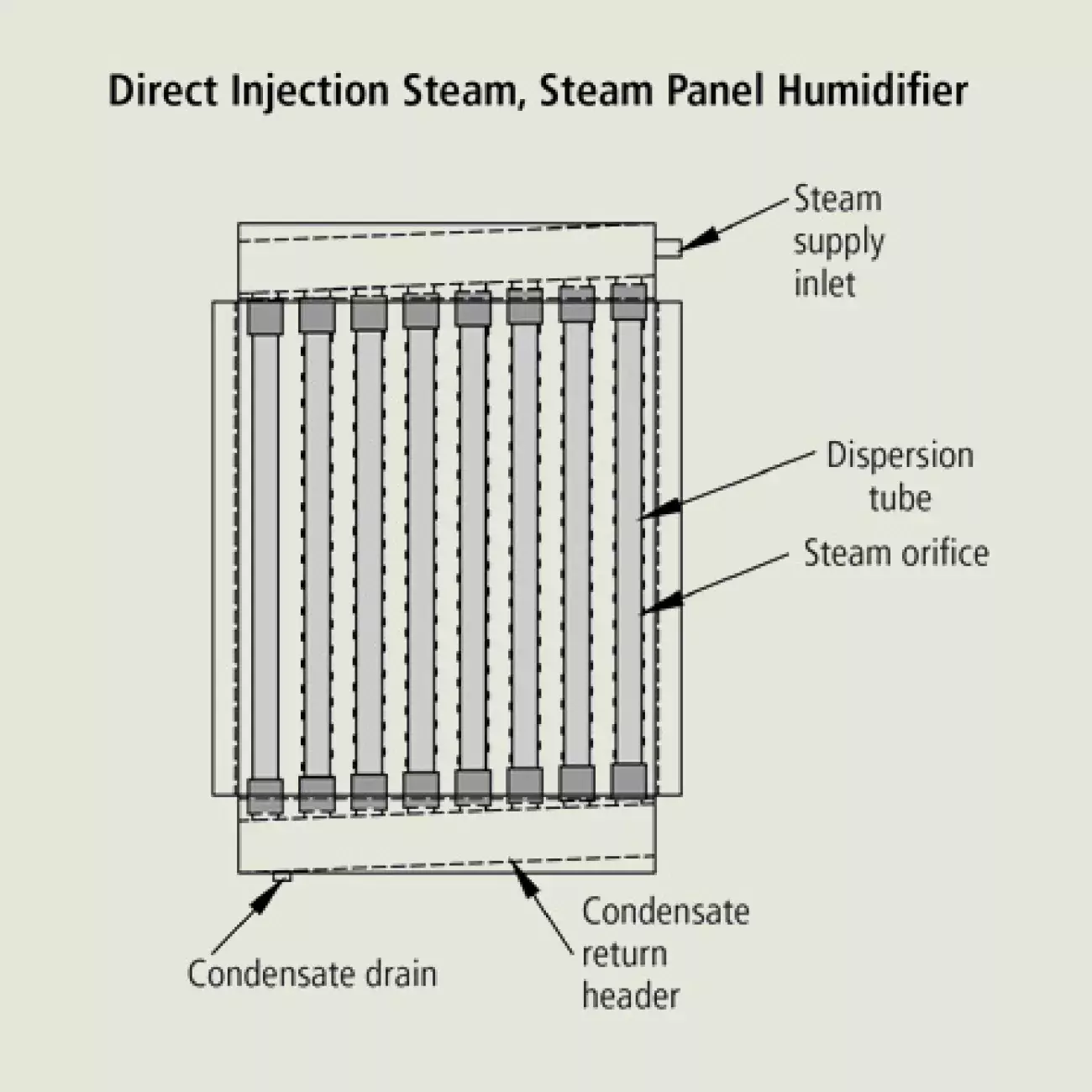

Steam panel-type humidifiers typically include a wye strainer, and a steam control valve. The panel consists of a steam supply header and multiple steam dispersing tubes. Steam flows through the control valve to the panel, passes through the dispersion tubes, and is introduced to the airstream. Condensate is discharged through the drain to one or two mechanical steam or P-traps.

Some steam panel-type humidifiers also have a heat exchanger that vaporizes dispersion-generated condensate and returns pressurized condensate to the boiler without additional pumps, valves, vents, or controls.

HEATED TANK HUMIDIFIERS

View a more detailed chart on heated tank humidifiers here. Please click on each heated tank humidifier below to access a brief description of that particular type.

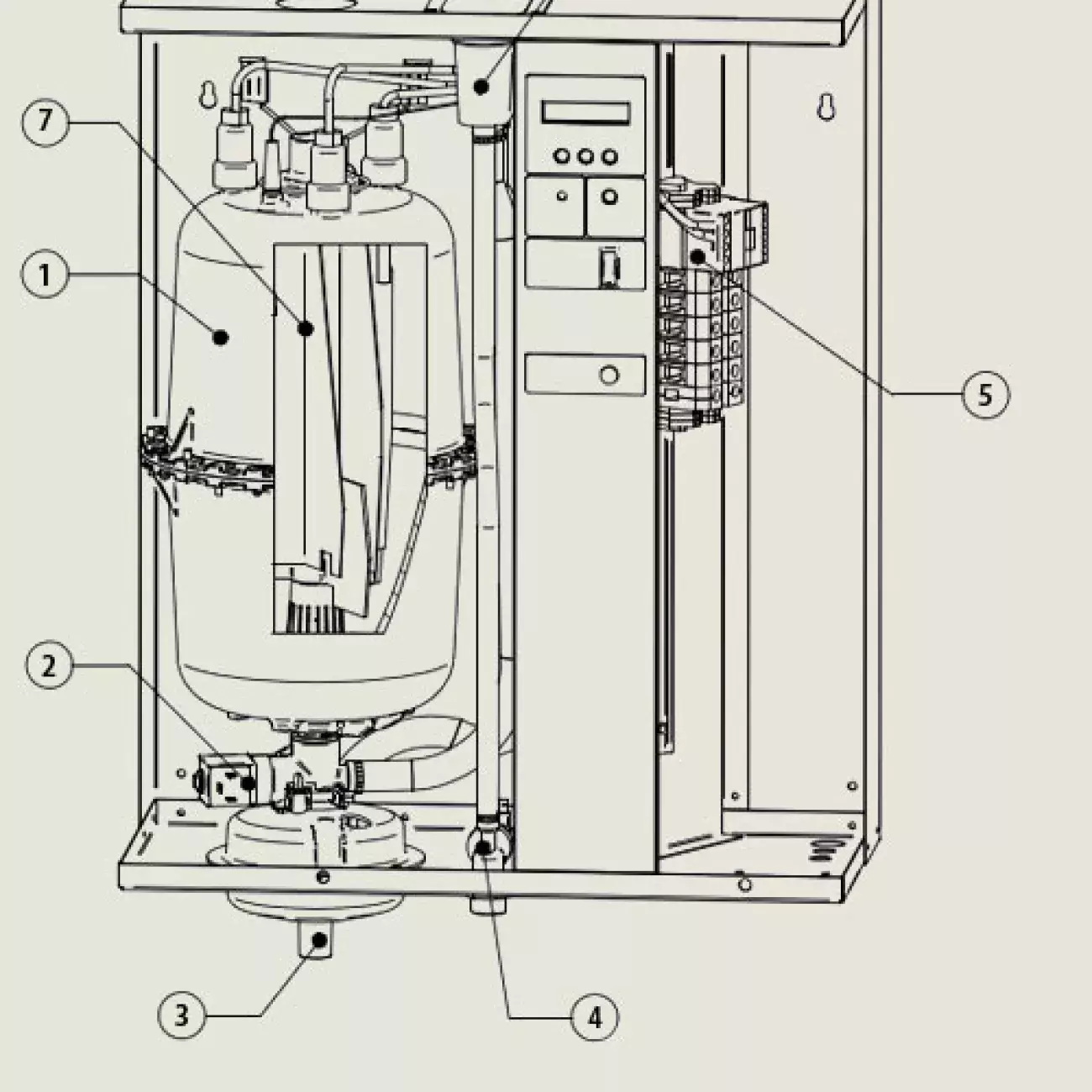

Electric (electrode type) humidifiers include microprocessor-based electronic controls, automatic fill and drain valves, and a steam generator cylinder complete with a set of electrodes inside. Electric current passes through ordinary tap or softened water, bringing it to a boil, and creating steam. Output is modulated by varying the water level in contact with electrodes. The drain valve initiates a periodic blowdown of the tank to adjust water conductivity and steam output. When scale buildup occurs within the steam-generating cylinder, the cylinder can be cleaned or, more commonly, replaced, significantly reducing maintenance requirements. Steam discharges out the top of the steam generator for dispersion into duct systems using dispersion tubes or into open spaces using fans.

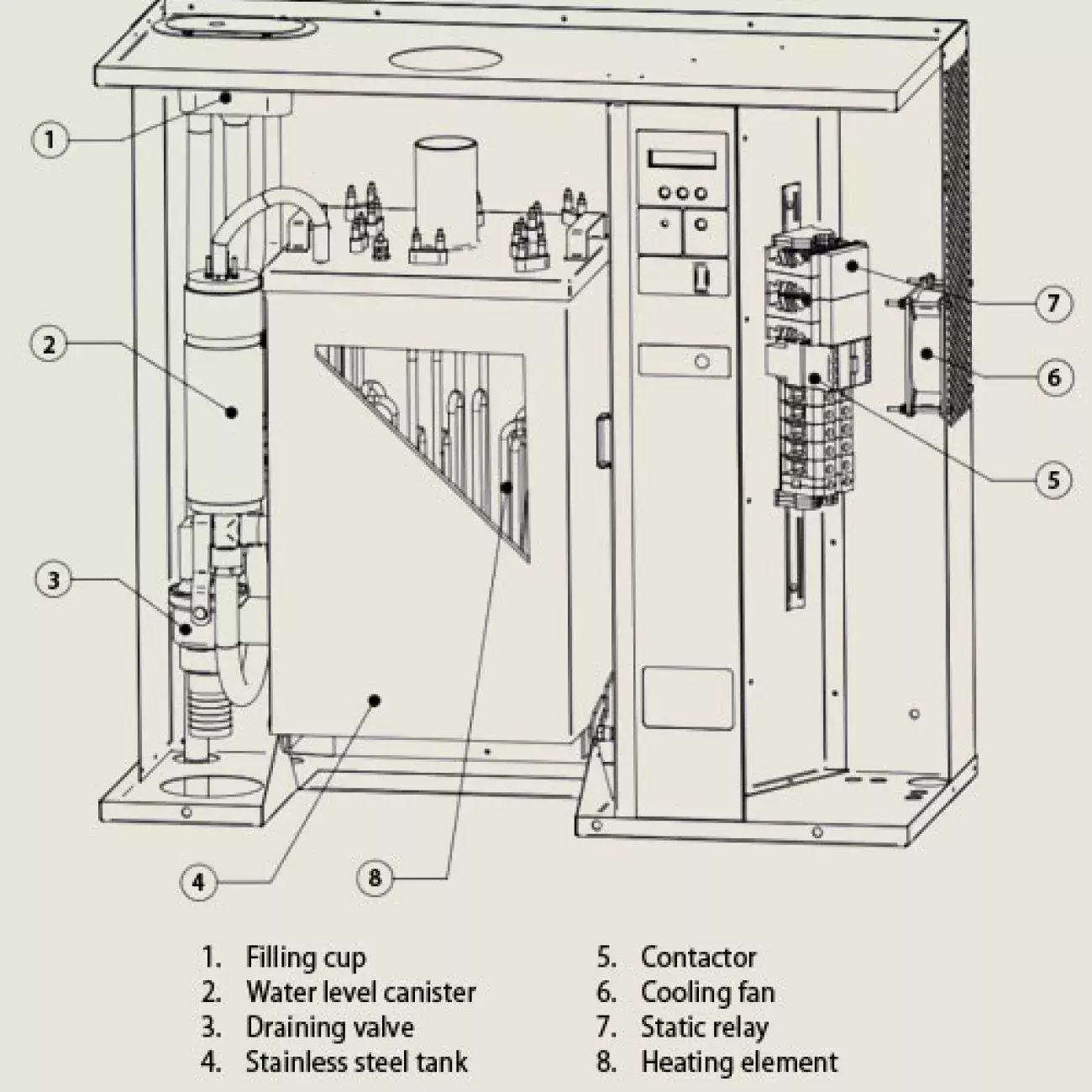

Electric (resistive type) humidifiers use one or more resistive heating elements, submersed in a cleanable stainless-steel tank, to heat and boil water. Steam discharges out the top of the tank. A drain valve initiates a periodic blowdown of the tank to reduce scale build up. Electric resistive-type steam humidifiers can use any type of fill water (tap, softened, RO/DI). They disperse humidification steam into duct systems using dispersion tubes or into open spaces using fans.

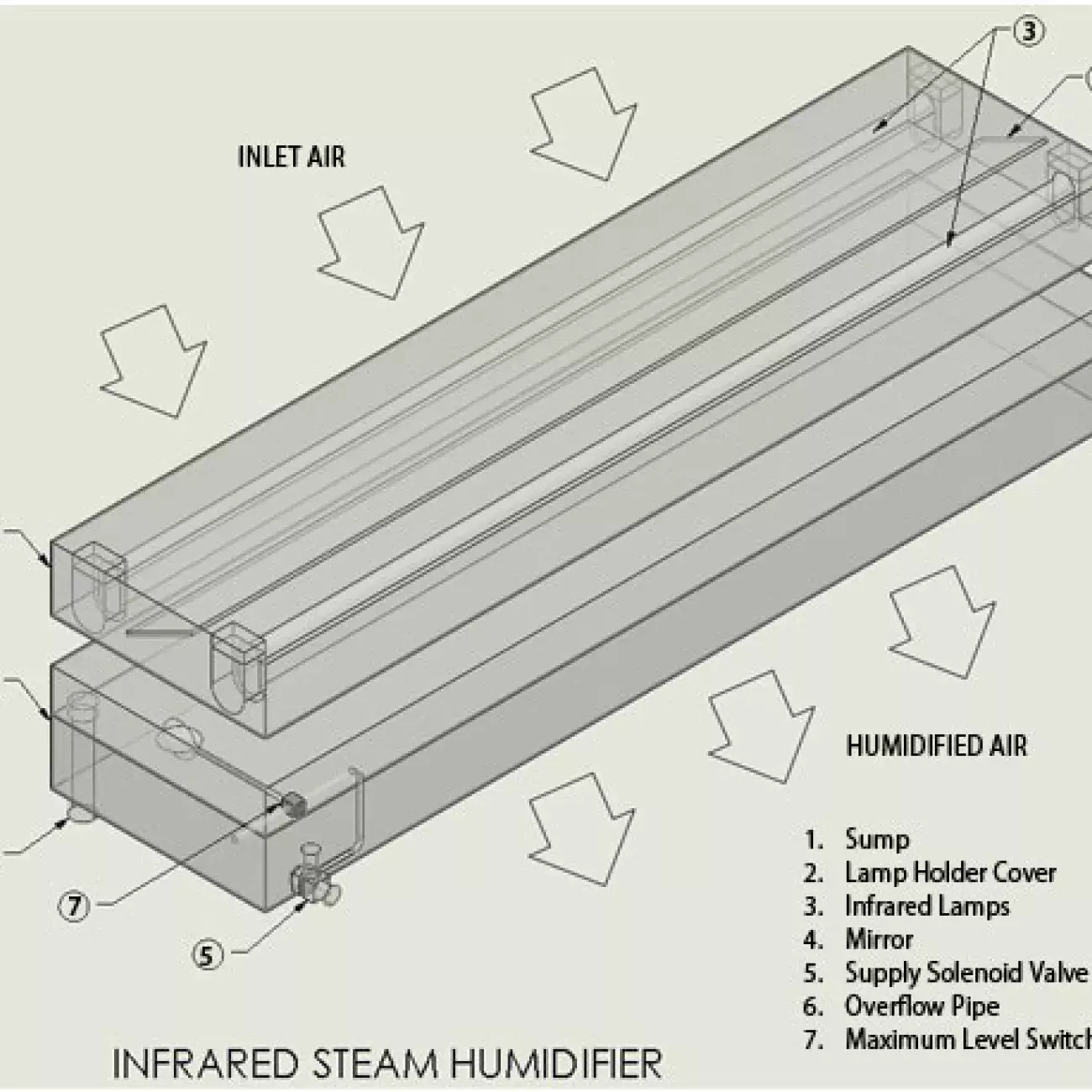

Infrared-tye steam humidifiers use one or more radiant heat bulbs to create heat energy to produce steam.

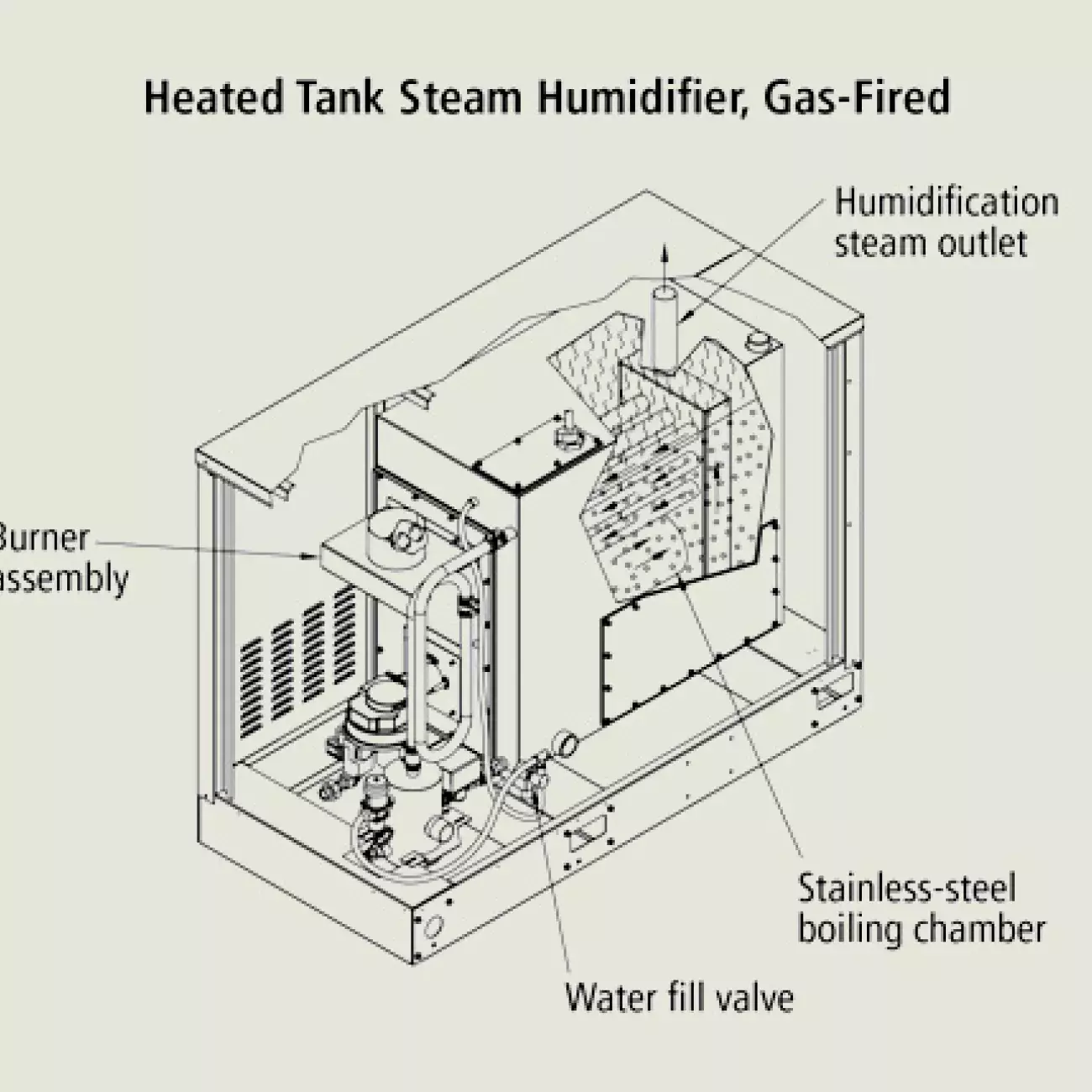

Gas-fired steam humidifiers use natural gas or propane, a burner/blower assembly, and a submersed heat exchanger to create atmospheric steam. A drain valve provides periodic tank blowdown to reduce scale buildup. Gas-fired steam humidifiers can use any type of fill water (tap, softened, RO/DI). They disperse humidification steam into duct systems using dispersion tubes or into open spaces using fans.

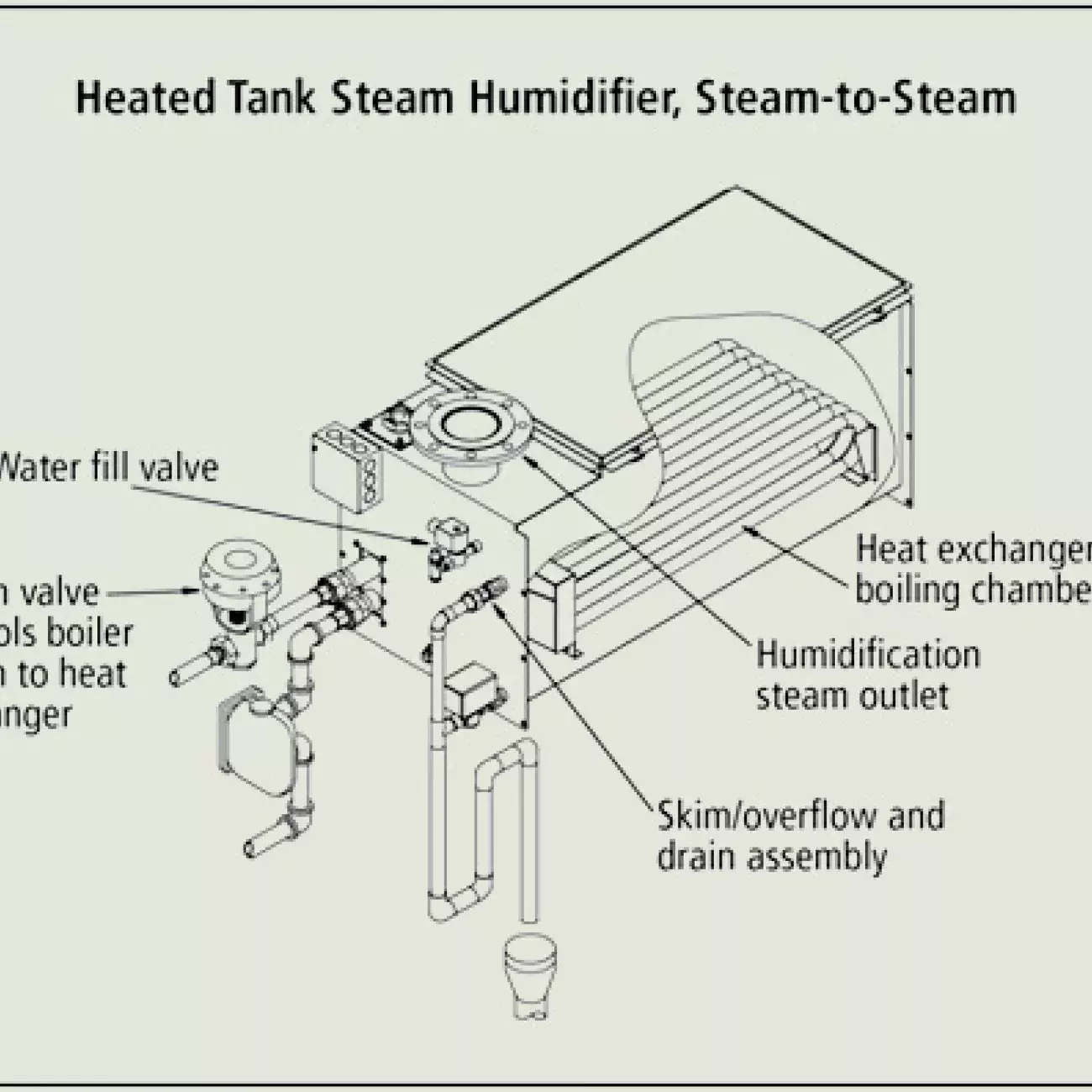

Steam-to-steam humidifiers use treated steam from a boiler at pressures up to 15 psig as a heat source in heat exchangers submersed in clean tap, softened, or RO/DI-treated fill water. Steam control valves control the steam pressure to the heat exchanger based on humidity demand, and the clean fill water is converted to atmospheric steam, exiting from the top of the tank. Condensate that forms is drained from a steam trap. A wye strainer is typically included and installed prior to the control valve. They disperse humidification steam into duct systems using dispersion tubes or into open spaces using fans.

Hot water type humidifiers utilize the heat energy from an existing hot water source passing through a heat exchanger submersed in water to produce steam. These humidifiers are very similar to steam-to-steam humidifiers.

Product Basics (Residential)

Residential humidifiers are classified by the way they add moisture to the air. There are three main classifications of residential central system humidifiers: atomizing humidifiers, steam humidifiers, and evaporative humidifiers. The capacity associated with a central system humidifier’s ability to add moisture to air expressed in gal/day of continuous operation. Humidification capacity, power input (in watts), and the energy input of any supplementary heat (in Btu/h or watts), if applicable, will be published for all humidifiers rated using AHRI Standard 610.

A central system or whole home humidifier is a device designed to add moisture to the home, and is installed directly into the central heating and cooling system. It is controlled by a humidistat, just like the temperature of the air is controlled by a thermostat. In order to add moisture to the air, humidifiers require heat, water, and air movement. Central system humidifiers can be mounted to the supply duct, return duct, or in a by-pass configuration, and should be installed by an HVAC professional. Most central system humidifiers require a hard-piped water supply. To maintain proper function, humidifiers should be maintained per the manufacturer’s instructions, on a regular basis, approximately once every six months. Whole-house humidifiers generally require much less maintenance than portable devices and have much longer lifetimes.

Residential self-contained humidifiers are used in homes with radiators or other non-ducted heating systems. Self-contained humidifiers are installed in the wall or ceiling of a house, and also have a humidistat to sense/control the home’s humidity level. They are connected to the water lines and hard-wired to the home’s electrical system. Self-contained humidifiers are alternatives to portable humidifiers.

Atomizing, or spray, humidifiers are similar to evaporative humidifiers in that they do not heat the water, but unlike their evaporative counterparts, atomizing humidifiers increase the moisture in the air by spraying small water droplets into the central system’s airstream. In nozzle-type units, a fine mist is injected into the air when water is forced through restrictive nozzles. Impeller humidifiers add moisture to the air through a spinning disk that flings water against a diffuser. Ultrasonic humidifiers, also known as piezoelectric humidifiers, atomize the water using a vibrating element that operates at a very high frequency of about 100 kHz (100,000 cycles per second).

Steam humidifiers heat water to the boiling point, producing steam. Because steam humidifiers contain their own heat source, electric heating elements, they are able to add moisture to cooler airstreams than atomizing or evaporative type humidifiers. Using electrode technology, electrical current flows between submerged electrodes, and the water resistance vaporizes the water. The submerged electrodes are stored in a canister, which is replaced at the end of a humidifier season.

Residential steam units are used when humidity is needed but other products cannot be installed or do not offer enough capacity. Most are wired to operate without warm air from the furnace, but instead utilize the furnace blower to distribute humidified air when the humidity level drops below a preselected level. Steam units can be mounted with a blower pack, if a ducting system is not available.

Evaporative humidifiers do not heat the water, but use hot air flow through a water panel and the HVAC system’s heat draw to turn the water to vapor. They are generally designed in either the bypass or fan powered style, depending upon how the air is delivered to the humidifier. In the bypass design, air is passed from the supply to the return. The fan powered version uses a fan to blow air through the unit. Dry, hot air from the HVAC system is moved through a water panel, and natural evaporation takes place. The now humidified air carrying moisture in vapor form is circulated throughout the home.

Flow Through-type

Flow through units maintain indoor relative humidity by flowing fresh water across a porous evaporator pad, where it is exposed to warm, dry air forced through the humidifier by the furnace blower or an internal fan. As the water evaporates, the heating system circulates humidified air throughout the home. Flow-thru humidifiers are designed to accommodate narrower ductwork, lower furnace temperatures, and shorter blower cycles.

Drum-type

Drum humidifiers rely on forced air, and are well-suited for warm-air heating systems. A rotating evaporator pad, or drum, lifts water from the water pan into the air stream, which is warmed and circulated by the furnace blower. The pad’s multiple holes and connecting strands increase the area from which water can evaporate.

Spray-type

Spray humidifiers are designed to be mounted on the warm air side of a furnace system and should only be used with naturally soft water. Spray humidifiers release a fine mist into the system’s ductwork, where it is distributed evenly throughout the home by the furnace blower.

Installation Guidelines

When installing commercial and industrial humidifiers, several factors must be taken into consideration to ensure proper system operation and installation.

PLEASE CONSIDER THE FOLLOWING:

Humidifier noise levels vary by technology, but in general, humidifiers should be installed away from quiet or occupied areas.

Direct steam injection systems can be noisy at the control valve, where boiler steam passes through on its way to a dispersion assembly.

Non-pressurized steam generators produce noise when filling and draining. Some electric steam humidifiers produce noise when contactors cycle on and off. For very quiet areas, consider an electric unit with quiet solid state relay (SSR) control rather than contactors. When not dispersing into a duct or air handling unit (AHU), locate dispersion fan units in quiet areas away from the steam generator.

Noise from adiabatic (unheated water) humidifiers varies by type. Residential bypass humidifiers generate minimal noise. Atomizing systems have water pumps and sometimes also air compressors that generate a fair amount of noise. With these systems it is usually possible to place the dispersion nozzles remotely from the pumping station, isolating noise to a mechanical room.

Create access to installed humidification equipment to allow convenient visual inspection and maintenance. Boiler-steam humidifiers contain devices (such as a control valve, a steam trap, and a strainer) that require periodic maintenance. While these devices can operate for long periods of time without attention, they should be accessible for inspection.

Non-pressurized steam humidifiers are either cleanable or have disposable cylinders. Location should allow for easy access with ample space for servicing.

Adiabatic humidifiers can require adjacent water treatment, so allow enough space for all system components. Locate residential bypass humidifiers where it’s easy for homeowners to replace evaporative pads, and place controls so they are easily accessed by the homeowner.

Protect areas surrounding humidifiers from water damage. The potential for water damage is always present with any steam or water appliance, but a properly planned installation virtually eliminates this risk. Be aware of valuable equipment or stored materials that are either adjacent or on a lower level. Install drip pans under humidifiers to contain water leaks when necessary.

For runs over 10 feet, use stainless steel or copper tubing to connect non-pressurized steam generators to dispersion assemblies, rather than using a steam hose. Though initially more expensive, there are several advantages to using rigid interconnecting pipe, including:

- Longer service life. Flexible hose will need replacing and may be more expensive in the long term.

- Easy to install at a uniform slope for condensate drainage. Rigid pipe won’t sag and create pockets, which can cause condensate to pool, resulting in spitting at the dispersion assembly.

- Easy to insulate. Insulating rigid pipe reduces steam loss due to condensation and can yield considerable energy savings.

Non-pressurized steam systems generate condensate in dispersion tubes and in the piping that connects the steam generator to the dispersion assembly. This water must be drained to prevent it from being discharged into the duct. Drain condensate back to the steam generator whenever possible.

There are two ways to return condensate to a non-pressurized steam generator. One method is to pitch the dispersion assembly and steam piping to return condensate to the generator. When this is done, condensate flows counter to steam flow. This method works satisfactorily only when steam piping is adequately sized for humidifier capacity and when a given minimum recommended pitch can be maintained. Otherwise, the velocity of the steam will carry condensate into the duct. Usually, humidifier manufacturers recommend a maximum steam flow rate and a minimum pitch.

The other method, used with higher capacity systems, involves returning condensate through a separate line. With this method, the dispersion assembly has a drain connected to a condensate return line, and both are pitched so that condensate returns to the humidifier. This installation requires an air vent in the return line.

When draining condensate to an open drain, a P-trap is required to prevent steam from escaping into the room. The trap is usually constructed of metal tubing. Water column height in the P-trap must be sufficient to withstand the operating pressure inside the humidifier. Consult the manufacturer’s recommendations for P-trap heights.

Many non-pressurized steam humidifiers have periodic drain and flush cycles or automated skimming where a portion of water in the tank drains to remove precipitated minerals. This water is typically 212 °F (100 °C) which, according to many municipal codes, should not be discharged to a sanitary system. In this situation, add a water tempering device to cool discharged water. Water tempering may be required for condensate to drain, as well.

This device is a must for steam and misting type humidifier installations and is mounted in the duct downstream of the dispersion assembly. It is usually set at 90 percent relative humidity (RH). If duct RH rises above that setting, it will shut down the humidifier. Wetted media humidifiers cannot over saturate airstreams and so a duct high-limit humidistat is not a requirement.

To ensure proper operation, the high-limit sensor must be located far enough downstream of the disperser to allow for full absorption and for humidity to equalize in the airstream. Otherwise, short cycling of the humidifier can occur, resulting in an unsatisfied humidification demand.

Most residential humidifiers can use an inexpensive on/off-type high-limit humidistat, except in variable air volume (VAV) systems. In this case, a modulating high-limit humidistat provides more satisfactory control.

If duct air flow stops for any reason, all humidifiers (except for wetted-media types) must be shut down immediately to prevent water damage. This can be accomplished by using a duct-mounted airflow proving switch. Use a switch that activates by the movement of the air or pressure in the duct. A sail switch or pressure differential switch may also be used.

Another type is a diaphragm-operated switch, in which the static pressure inside the duct actuates the switch. The latter type isn’t a good choice for VAV systems, because when the VAV box modulates the airflow, the duct static pressure remains high and allows the humidifier to continue to operate without sufficient volume of steam-absorbing airflow. A sail-switch is the best choice for VAV applications.

The location of the humidity sensor or transmitter has a significant impact on humidifier performance. Placing a sensor in the center of a room or inside a return air duct will give the best all-around control.

Do not place a sensor near a supply duct, on a perimeter wall, in sunlight or near a heat-producing object. The humidity sensor should be located where it can measure an average space temperature and humidity.

Residential in-duct humidifiers

Residential in-duct humidifiers should be specified and installed by licensed, qualified heating and air conditioning professionals. The installer is responsible for choosing the correct humidifier based on many factors, including the home’s humidity demand, type of heating system, floor plan, accessibility, and water characteristics.

Maintenance Guidelines

When properly designed, specified, installed, and maintained, humidification systems operate trouble-free for years.

When operational issues occur, review the humidifier’s troubleshooting guide, but also consider that other HVAC issues, such as temperature or airflow, affect humidifier performance.

CONSIDER THE FOLLOWING HUMIDIFIER MAINTENANCE GUIDELINES:

The best prevention against field issues is regular inspection and maintenance. Maintenance requirements vary depending on humidifier type (e.g., cleanable boiling chambers vs. disposable) and water type (hard, naturally soft, softened, or demineralized water). All systems should be inspected after the first three months of duty to determine future inspection and maintenance requirements.

Operating a humidification system within the parameters for which it was designed will keep systems running smoothly. For example, if a system was designed to meet a 35 percent relative humidity (RH) requirement in a humidified space, but building occupants are operating systems at 55 percent, available absorption distance in a duct can become inadequate, resulting in duct wetness. It is important to communicate system expectations to building occupants.

All humidifiers convert water to vapor, and supply water type has the most impact on maintenance requirements.

Untreated tap water includes minerals — such as magnesium, calcium, and iron — that make water “hard.” These minerals clog boiling chambers, wetted media pads, and atomizing nozzles. Adiabatic (unheated water) systems can disperse minerals into the air causing white dust, which can contaminate furnishings and processes as well as cause inhalation hazards. Using softened water can mitigate many of these issues. Systems using properly processed demineralized water, such as deionized or reverse-osmosis filtered water have virtually no supply water maintenance issues.

Equipment using treated water should be tested regularly to ensure proper quality. Equipment using deionized water requires changing deionizing beds in a timely manner to ensure that chlorides, which corrode stainless steel, are not introduced into the system.

Start with an easy maintenance task and check and tighten electrical connections such as contactors, fuses, and sensors.

Verify signal compatibility and properly placed sensors. For example, a signal going to a humidifier from a transmitter, humidistat, or building automation system must be compatible with a signal a humidifier is set to receive. A controller will not understand a modulating humidistat sending a 4- to 20-mA signal if it is not wired or programmed to receive that signal.

Signal inputs typically can be changed at a controller board and/or through a controller’s software. A control manual will have specific instructions. All control components should be wired per an appropriate wiring diagram.

A high-limit humidistat normally should be installed in a supply duct about 12 to 15 feet downstream of where a dispersion assembly delivers steam. If it is installed too close to the dispersion assembly it either will quit operating because it is wet or shut off the humidifier because it will accurately read that duct RH is very high (high-limit humidistats are adjustable and usually are set to switch open between 80 and 90 percent RH).

Steam dispersion assemblies operate trouble-free if designed and installed correctly. They disperse distilled water so there are no issues with clogging, there are no moving parts, and they are constructed mostly of welded metal, often stainless steel. Adiabatic (unheated water) humidifiers can clog if water is untreated. Ultrasonic humidifiers have disks that need replacing periodically.

Steam generators with cleanable stainless-steel tanks operate at peak performance when clean. Mineral accumulation insulates heaters, reducing output and potentially causing heater failure. Use a manufacturer-recommended cleaning solution for stainless steel tanks. Use softened or demineralized water to reduce mineral accumulation. Or, consider using a steam generator that has a replaceable plastic cylinder, requiring no cleaning. When mineral accumulation reaches a predefined level, the humidifier’s controller will typically present a “change cylinder” message.

Applicable Standards

Residential Humidifiers usually have the capability of distributing up to 10 pounds of water per hour (1.2 Gal. per hour or 28 .8 Gal. per day) into the home. Their performance is usually tested by the manufacturer or an independent laboratory to one of the following standards:

- ANSI/AHRI Standard 610 (I-P/2014), Performance Rating of Central System Humidifiers for Residential Applications.

- ANSI/AHRI Standard 611 (SI/2014), Performance Rating of Central System Humidifiers for Residential Applications.

- ANSI/AHRI Standard 620 (I-P/2014), Performance Rating for Self-Contained Humidifiers for Residential Applications.

- ANSI/AHRI Standard 621 (SI/2014), Performance Rating for Self-Contained Humidifiers for Residential Applications.

- ANSI/AHRI Standard 640 (IP/2017), Performance Rating of Commercial and Industrial Humidifiers.

- ANSI/AHRI Standard 641 (SI/2017), Performance Rating of Commercial and Industrial Humidifiers

- ANSI/ASHRAE Standard 164.1, Method of Test for Central System Humidifiers for Residential Applications.

Commercial and Industrial humidifiers usually have a capability of distributing higher capacities of water into the space than the above residential humidifiers. Their performance is usually tested by the manufacturer or an independent testing laboratory to ANSI/AHRI Standard 640, Performance Ratings for Commercial — Industrial Humidifiers.

These standards define the specific testing method and design of the test facilities, temperatures, airflow, water pressure, and weighing method that is to be used so all humidifiers are tested to the same conditions.

Residential and commercial and industrial humidifiers are usually tested for electrical and other safety considerations using one or more of the following standards:

- UL 998 Standards for Safety Humidifiers

- UL 499 Standards for Electric Heating Appliances

- CSA C-22.2 No. 104-01 (R2006) Humidifiers ( bi-national standard with UL 998)

They specify construction requirements that have been proven over the years to provide safe operation of the equipment.

Humidifiers tested and approved by independent testing agencies to the above electrical standards will have the UL or CSA logo listed on the electrical data plate of the humidifier.

Table top and portable type humidifiers are usually tested using standard ANSI/AHAM HU-1-2006 Household Humidifiers (Tabletop and Portable Type). These humidifiers also are usually tested and approved using one of the above UL and/ or CSA standard.