Equipment Owners

Making Your Business Compliant

To comply with federal and state laws regulating refrigerant emissions, HVACR contractors should develop policies and procedures for their employees to follow.

The following checklist will help you make your business compliant with these laws. This list is not meant to be exhaustive, but rather a simple checklist to cover the basics.

- Your technicians must have EPA Section 608 certification if they are servicing refrigeration and air conditioning equipment containing CFCs or HCFCs.

- Require all technicians to locate and repair leaks instead of “topping-off” leaking systems. Prohibit technicians from intentionally releasing any refrigerant when servicing, repairing, or maintaining equipment. In most cases, they should use EPA certified refrigerant recovery equipment during service, maintenance or repair.

- Complete and submit EPA's Refrigerant Recovery and Recycling Device Acquisition Certification Form to certify, in writing, that you have and will properly use EPA-certified refrigerant recovery and recycling equipment.

- Require technicians to recover refrigerant during servicing.

- Make sure your technicians understand the difference between “recovered,” “recycled” and “reclaimed” refrigerant.

- A recovered refrigerant is one that was removed from refrigeration or air conditioning equipment and stored in an external container WITHOUT necessarily being tested or processed in any way. Reuse is restricted to the system that it was recovered from, or in any other system owned by the same equipment owner.

- A recycled refrigerant has been extracted and cleaned for reuse WITHOUT being tested for compliance with the stringent AHRI Standard 700 purity specifications required for reclaimed refrigerant. Reuse of recycled refrigerant is restricted to the system that it was recovered from, or in any other system owned by the same equipment owner; otherwise, it must be sent to an EPA-certified reclaimer to restore it to AHRI Standard 700 purity specifications prior to resale.

- A reclaimed refrigerant has been reprocessed using specialized machinery and tested to meet AHRI Standard 700 purity specifications.

- Before disposing of equipment, you are legally responsible for properly recovering HCFCs from existing refrigeration and air conditioning systems. You may send recovered HCFC refrigerants to be reclaimed or destroyed.

Residential Air Conditioning

The age of your air conditioning system, the cost to maintain it, and the cost to replace it are all factors to weigh as HCFC refrigerants are phased out. Your best preparation for the future is to learn what type of refrigerant your cooling system uses, determine if it uses a refrigerant that is being phased out, and learn about your replacement and servicing options.

Your Current System

Purchasing a New System

Downloadable Informational Brochures

- What You Need to Know about the HCFC Refrigerant Phaseout

- If you choose a new system using a non-ozone depleting refrigerant, learn why it needs to be an AHRI Certified™ matched system.

Availability of R-22

While R-22 remains available for servicing equipment made before 2010, it is important to know that supplies of R-22 will become more limited over time. Contractors can send refrigerant they remove from an air conditioning system to a reclaimer who will reclaim the refrigerant to restore it to a purity level that meets AHRI Standard 700. This reclaimed refrigerant can be used again to recharge R-22 air conditioning systems. This will help extend the supply of R-22.

Alternatives/Retrofitting

Determine the refrigerant used

How do you know if your home’s central air conditioner or heat pump contains R-22? Homeowners can easily check their equipment. The refrigerant is usually identified by a nameplate on the air conditioning unit. If a nameplate is not provided, you could check your owner’s manual for the information. Also, if you know the manufacturer and the model number of the unit, you could call the manufacturer directly or check its website.

Owning an air conditioner that requires R-22 refrigerant after 2010

You may continue to have your equipment containing R-22 refrigerant serviced after 2010. Keep in mind, after 2010 only a limited amount of new R-22 refrigerant will be produced to meet the servicing needs of equipment manufactured on or before Dec. 31, 2009. After Jan. 1, 2020, production of R-22 will be prohibited and only recovered, recycled or reclaimed supplies of R-22 will be available for servicing existing equipment.

Alternative Refrigerants

The EPA has identified a list of acceptable alternatives to R-22 that do not harm the ozone layer that homeowners can use in their equipment. The EPA’s Significant New Alternatives Policy (SNAP) Program is a list of acceptable substitutes. R-410A, an HFC refrigerant blend, is the most common and does not harm the ozone layer. Not all of these refrigerants are considered retrofit alternatives for R-22 air conditioning systems.

Proper Servicing

Servicing Systems with R-22

While R-22 remains available for servicing equipment made before 2010, it is important to know that supplies of R-22 will become more limited over time.

Working with a qualified service technician who will provide ongoing, regular service to your system is an important measure for maintaining its efficiency and refrigerant charge, as well as reducing your system’s impact on the environment. To identify a qualified service technician, go to HVACR Advice to locate local technicians certified through North American Technician Excellence (NATE).

Technicians servicing R-22 air conditioning systems must have EPA Section 608 certification and carry a card verifying this credential.

It also is illegal for them to intentionally release any refrigerant when making repairs. To avoid emitting refrigerants, technicians must use EPA-certified refrigerant recovery equipment during service.

Be sure to request that service technicians locate and repair leaks instead of "topping off" leaking systems. This protects the ozone layer and saves you money by optimizing the performance of your existing equipment.

It is important to note the newest refrigerant used in home air conditioning systems today is R-410A, and it cannot be used in any system not specifically designed for it.

Determine If It Is Time to Upgrade

When deciding if it is time to upgrade or purchase new equipment, consumers need to consider several key factors, such as energy efficiency, performance, reliability, cost and replacement alternatives available. After 2020, the servicing of R-22 systems will rely on recycled or stockpiled refrigerants. For the next 10-15 years, R-22 should continue to be available for all systems that require it for servicing; however supplies will decrease.

The single most important thing you can do to reduce the potential need to have your system’s refrigerant serviced is to have proper, regular maintenance for your system done by a qualified contractor. Routine servicing minimizes potential environmental hazards and keeps maintenance costs low. Look for an HVAC contractor who employs technicians certified by North American Technician Excellence (NATE). A system that is not installed or maintained properly will result in reduced efficiency and deliver less comfort.

Always request that service technicians repair leaks instead of “topping off” leaking equipment, regardless of the system size. This saves you money by optimizing the performance of your system.

Remember, it is illegal to intentionally release refrigerant substitutes when making repairs to your equipment. Technicians must always avoid release of refrigerant when servicing of your unit.

No-Venting Rule Exceptions

While it is illegal to knowingly vent ozone-depleting refrigerants like CFCs and HCFCs, Section 608 of the Clean Air Act does grant a few exceptions.

- De minimis venting, which is probably the most well-known exception, simply means that refrigerant released in small amounts during a “good faith” effort to recover, recycle or dispose of the refrigerant is not illegal.

- Refrigerant emitted during the normal operation of HVACR equipment is not illegal, but EPA does require the repair of all substantial leaks.

- Mixtures of nitrogen and R-22 that are used as holding charges or as leak test gases.

- Small releases of refrigerant that result from purging hoses or from disconnecting hoses after charging or servicing equipment.

Replacement Options

The phaseout period was established with the intent of phasing out the use of R-22 refrigerant without requiring homeowners to replace their R-22 air conditioning equipment earlier than normal.

New R-22 and R-410A systems are available today. Manufacturers also provide systems that use R-22 and R-410A that are Energy Star-qualified.

Energy efficient air conditioners save energy costs while still allowing you to maintain a proper comfort level. What determines if an air conditioner system is energy efficient? Energy efficiency is measured by the seasonal energy efficiency ratio (SEER) rating. In general, the higher the SEER, the less energy is needed for the cooling system to do its job.

To find certified air conditioning and heat pump systems, go to the AHRI Directory of Certified Product Performance. Be sure to ask your air conditioning or heat pump installer to provide you with an AHRI Certificate of Product Ratings that verifies the system’s certified performance ratings.

Finding a Qualified Installer

Working with a qualified service technician who will provide ongoing regular service to your system is an important measure for maintaining its efficiency and refrigerant charge, as well as reducing your system’s impact on the environment.

To identify a qualified service technician, go to HVACRadvice.com to locate local technicians certified through North American Technician Excellence (NATE).

Technicians servicing R-22 air conditioning systems must have EPA Section 608 certification and carry a card verifying this credential.

Commercial Air Conditioning

If you are an owner of commercial air conditioning equipment, you bear legal responsibility and face serious penalties if you don't comply with EPA refrigerant regulations. You also must cooperate with EPA or state officials during facility inspections and have the ability to produce required documentation during inspections.

To help you comply, this area of PhaseOutFacts.org includes recommendations on how to implement a framework of procedures, systems, and information to ensure you meet EPA's requirements.

Two Steps to Compliance

- Step 1: Designate a Facility Refrigerant Compliance Manager

- Step 2: Develop a Refrigerant Compliance Management Plan

Refrigerant Compliance Manager

To ensure compliance with EPA's refrigerant regulations, the first step for any facility is to appoint an individual who will have the responsibility and authority to create a refrigerant management plan and to oversee its successful implementation. Providing this individual with the authority and budget to effect change and to coordinate the plan across all company functions and departments is essential. Your refrigerant compliance manager also should have a good understanding of your facility's current HVACR operations, industry standards and related regulations.

Principal duties for this position should include:

- Coordinate refrigerant purchases and maintain inventory of use records;

- Gather and disseminate information on refrigerant technology, codes, and regulations;

- Develop and apply administrative controls;

- Develop and implement a refrigerant policy;

- Perform a systems assessment and evaluate alternatives;

- Plan for future refrigerant and equipment needs;

- Develop a refrigerant management plan schedule;

- Ensure regulatory compliance;

- Participate in budgeting processes;

- Ensure safe handling of refrigerants by all personnel; and

- Minimize risks associated with refrigerant handling.

The manager's authority should encompass procurement of equipment and services to comply with regulations; technician training; refrigerant transportation and disposal; safety equipment; and management of refrigeration equipment retrofit or replacement.

Compliance Management Plan

To comply with the Clean Air Act, an equipment owner needs a defined and documented refrigerant compliance program. The checklist below provides a number of required and recommended actions your facility should take to make sure you are in compliance. Simple Checklist

Develop Policy and Procedures

- Develop an unintentional refrigerant venting, leaking, and reporting policy for your refrigerant appliances, equipment, and refrigerant inventory.

- Develop a policy for conducting annual internal refrigerant-compliance GAP-analysis surveys to ensure that your organization is in compliance with all EPA requirements.

- Develop a refrigerant-inventory management policy including disbursement, cradle-to-grave record keeping, and audit tracking of all refrigerants.

- Develop a process and infrastructure to collect, distribute, and communicate the various refrigerant regulations updates and amendments issued by the EPA.

Required Documentation

- Keep copies of the various EPA regulations and requirements applying to refrigerants and their uses and make sure employees managing air conditioning and refrigeration equipment understand these regulations and requirements and how they impact their jobs. Be sure to stay abreast of the various updates, amendments, and changes the EPA has issued on the original refrigerant regulations.

- Make sure you and your HVACR employees are aware of EPA's non-compliance penalties and enforcement actions.

- Maintain EPA certifications for all in-house and contracted technicians working at your facility.

- Develop a written statement that documents your "intent to comply" with EPA refrigerant-regulations. PhaseOutFacts.org provides a SAMPLE Refrigerant Management Policy for Facilities.

Sample Policy PDF

Sample Policy Word Document

Operations Fulfillment, Personnel

- Have a written job description for a facility manager, responsible for refrigerant management and compliance with regulations, as EPA recommends in its Action Guide.

- Officially designate someone as your refrigerant compliance manager. The EPA will want to speak to this person during a refrigerant-compliance inspection.

- Have your refrigerant-compliance manager formally trained in EPA refrigerant regulations compliance management to ensure effective and complete implementation of your refrigerant compliance program.

- Make sure your refrigerant-compliance manager has the financial resources and authority to implement your organization's refrigerant compliance program.

- Develop a written refrigerant purchase policy and a designated certified technician or contractor responsible for all purchases.

- Provide all maintenance personnel with written EPA refrigerant compliance policies and procedures manuals.

- Communicate EPA refrigerant compliance policies and procedures to all affected personnel by holding documented compliance training sessions.

- Conduct ongoing EPA refrigerant regulations training for your technicians and other affected personnel that includes updates, amendments and changes issued by the EPA.

Operations Fulfillment, Record Keeping

- Establish an EPA-required refrigerant usage record keeping policy, including a defined and uniform method of collecting, maintaining, and making records available to EPA inspectors upon request.

- Establish a written appliance-servicing policy including EPA compliance requirements and specific refrigerant handling procedures.

- Establish a written labeling policy for refrigerant cylinders and appliances using refrigerants per EPA requirements;

- Establish a written refrigerant inventory and storage policy incorporating national and state regulations and building codes.

Operations Fulfillment, Safety/Liability Concerns

- Develop a written leak-testing process and defined service procedures for positive-pressure equipment to ensure EPA compliance.

- Develop a written refrigerant emergency-response plan including policy for major venting incidents, maximum exposure levels, and evacuation procedures.

- Add "contractor EPA refrigerant-compliance requirements" language into your service-maintenance agreements to ensure that your contractors are not exposing you to liability.

Operations Fulfillment, Equipment/Materials Handling

- Develop a written policy for disposal of refrigerant equipment and parts.

- Develop a written policy for disposal of used refrigerant lubricants.

- Develop a written policy for shipping and transporting refrigerants, both into and out of your facility.

- Develop a written refrigerant safety policy for handling all refrigerants, including required safety equipment and procedures.

Commercial Refrigeration

The HCFC refrigerant phaseout will likely have a significant impact on commercial refrigeration equipment owners, particularly those with extensive refrigeration systems like supermarkets. These equipment owners can pay a substantial cost to maintain their system, have a great deal of capital invested in their refrigeration equipment and can find it difficult to justify changes.

To help you prepare, PhaseOutFacts.org provides the following information in this area of the site

- Understand the Rules and Regulations

- Develop a Compliance Management Plan

- Assign a Refrigerant Compliance Manager

- Reduce Refrigerant Charges and Leak Rates

- Know Your Recordkeeping Requirements

- Follow Required a Determined Leak Rate Calculation

- Have a Leak Response Program

- Know the Certification Requirement for Professionals Servicing Your Equipment

Refrigerant Rules and Regulations Affecting Commercial Refrigeration Equipment Owners

It is important for commercial refrigeration equipment owners to be aware of their federal legal requirements. To help you comply, PhaseOutFacts.org provides the following links to refrigerant rule and regulations, compliance checklists and guidelines, refrigerant leak and full charge calculations, timelines, and regulatory updates.

- U.S. EPA Regulatory — Ozone Depletion Rules and Regulations

- Definitions of leak rate, commercial refrigeration appliance, and full charge at 40 CFR 82.152

- Prohibition against venting at 40 CFR 82.154(a)

- Required leak repair practice at 40 CFR 82.156(i)

- Recordkeeping requirements at 40 CFR 82.166(k)

Refrigerant Charges and Leak Rates

The amount of refrigerant a system loses over time can greatly impact a commercial refrigeration system’s efficiency. According to the Environmental Protection Agency (EPA), on average, 25 percent of the refrigerant charge in U.S. supermarket systems is lost each year. The efforts to reduce leak rates and improve refrigeration system efficiency overall is an industry and government priority.

- Be aware of regulatory rules and requirements such as acceptable methods for calculating leak rates, leak repair practices, and recordkeeping requirements.

- Participate in EPA’s GreenChill program. Its goal is to promote advanced technologies, strategies, and practices that reduce refrigerant charges and emissions of ozone-depleting substances and greenhouse gases.

- Work with a qualified NATE-certified technician. North American Technician Excellence is the industry-recognized certification body for HVACR technicians. NATE offers a light commercial and commercial refrigeration service exam for technicians.

Leak Rate Calculation Requirements

Owners of commercial refrigeration equipment using an HCFC refrigerant with a charge greater than 50 pounds must document the full charge of the appliance and calculate the leak rate each time refrigerant is added to the system. These guidelines were developed to monitor the amount of refrigerant used, as well as the extent of any leaks.

EPA outlines four acceptable methods that can be used either individually or in combination to assess full charge:

- Equipment manufacturers’ determination.

- Calculations based on component sizes, refrigerant density, volume of piping and other considerations.

- Actual measurements of the amount of refrigerant added or evacuated from the appliance.

- Use of an established range based on the best available data. This method requires you to document how you determined the full charge.

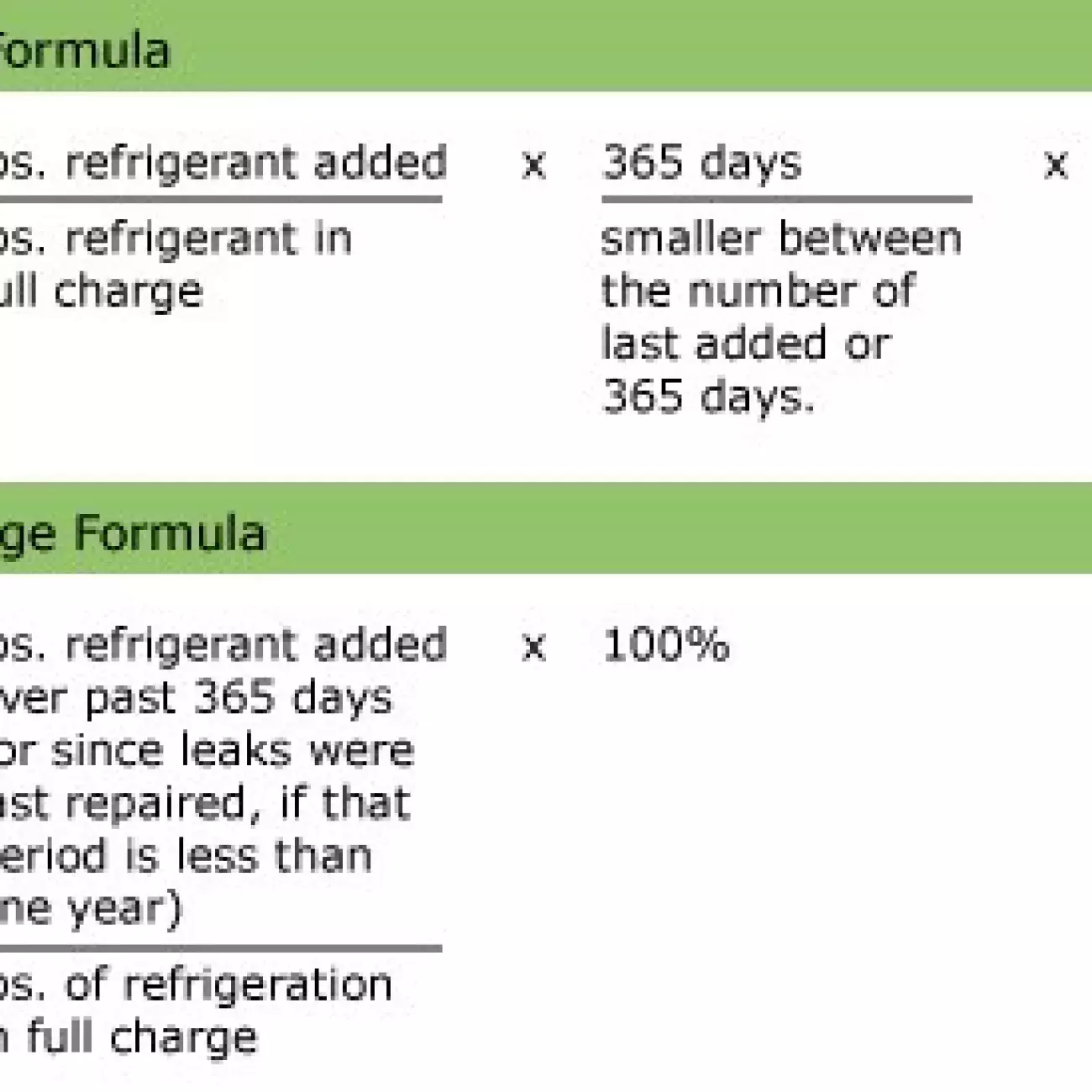

Full charge is necessary to determine the leak rate. For commercial refrigeration equipment, EPA says the trigger leak rate for a 12-month period is 35 percent of the full charge. According to the latest rule, there are two acceptable methods for calculating leak rate: annualizing and rolling average. However, the equipment owner must select and consistently use only one method over the lifetime of all the appliances located at a facility.

Industrial Process Refrigeration

Industrial process refrigeration are complex, customized systems used in the chemical, pharmaceutical, petrochemical, and manufacturing industries. These systems are directly linked to the industrial process. This sector also includes industrial ice machines, appliances used directly in the generation of electricity, and ice rinks.

The U.S. Environmental Protection Agency has provided guidance to help industrial process refrigeration equipment owner's comply with refrigerant rules and regulations.This guidance is focused on aspects of the amendments relevant to industrial process refrigeration systems. All refrigeration systems, including industrial process refrigeration, are subject to various requirements of the refrigerant recycling regulations. Therefore, you should also read the amendments and other pertinent sections of those regulations.

EPA Guidelines and Compliance Documents